Resources

Evidence of our expertise and how WE SOLVE PROBLEMS for our customers

Solutions

Industries

ParkerStore™ is your go-to destination for hose, fitting, instrumentation, hydraulic, pneumatic, and filtration products and services. Our mission at MCE is simple: to help you improve productivity...

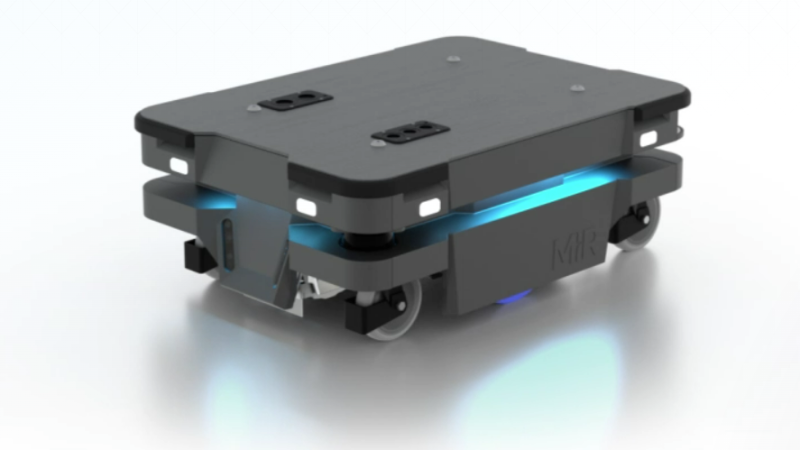

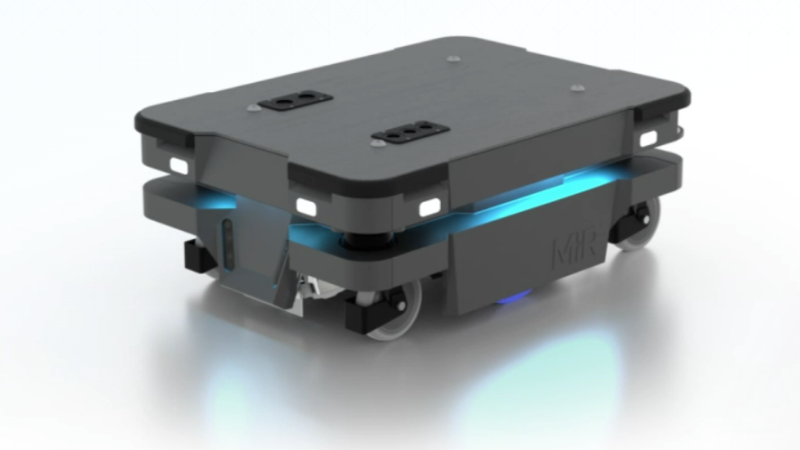

By integrating MiR autonomous mobile robots with custom engineering, MCE helped a manufacturer transform a labor-intensive, injury-prone task into a safe, hands-free process that keeps production...

In water, wastewater, and industrial facilities, pumps are the heart of the operation. But like any piece of equipment, they don’t last forever. Knowing when to repair versus replace can save you...

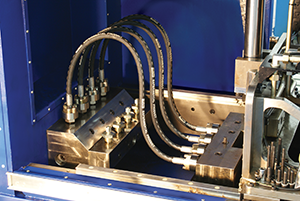

The Challenge A division of a major aerospace manufacturer required a reliable method to test and certify critical hydraulic components (valves, cylinders, reservoirs) used in their fighter jets. The...

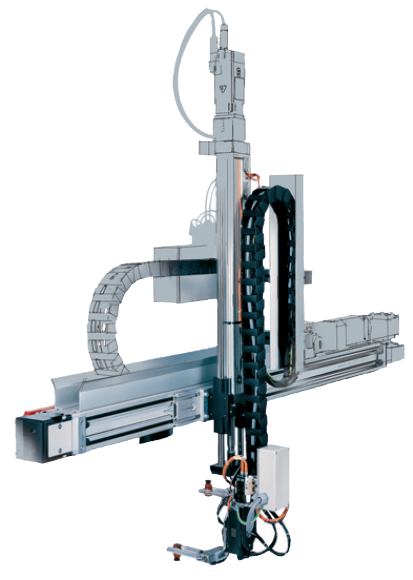

Automation from Start to Finish for Your Industrial Application with MCE Solutions.

Certified to Withstand the Sea: How MCE Keeps Navy Systems Mission-Ready

Reduce the injury risk to your employees with MCE’s ergonomic modular material and pallet conveyor solutions.

Vertical farming is gaining traction as a reliable solution to address land scarcity and climate uncertainty. Controlled environment agriculture enables the growth of fresh produce near urban...

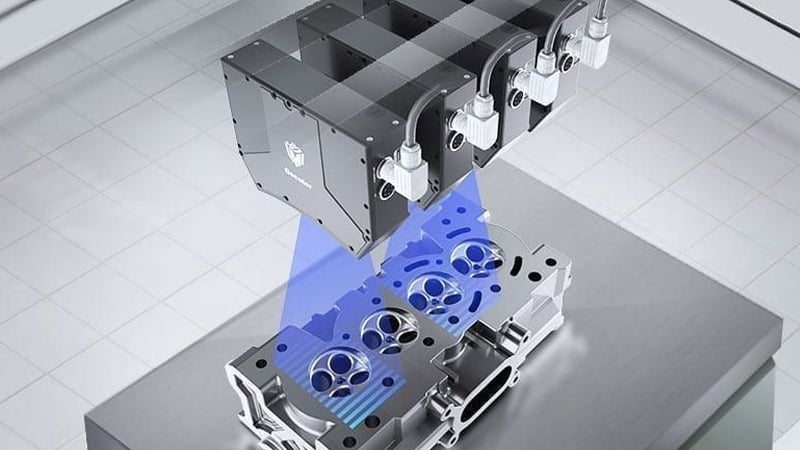

From defect detection to robotic guidance—MCE makes it work together. With deep expertise in vision and automation, we design 2D and 3D inspection systems that deliver clarity, reduce errors, and...

Reduce noise, boost safety, and extend production equipment life with MCE.

MCE supplies shipbuilders with everything needed to keep pace with complex projects. Our history dates back over 115 years.

How did MCE's BioFuels Automation become the leading expert in ethanol processing?

Industrial plants lose millions every year due to equipment failures caused by inconsistent lubrication. MCE’s automated lubrication systems eliminate guesswork, delivering precise lubrication...

Pressed for additional warehouse space? Stop thinking about square footage—and start imagining cubic footage.

Downtime doesn't just slow you down—it compounds the pain.

Closing the Gaps in Paint Production: How MCE Delivered a Full-System Filtration Upgrade

With growing pressure to deliver faster and more cost-effectively, medical manufacturers are increasingly turning to robotics and automation to enhance quality while reducing human error. Medical...

How much did plant downtime cost your industrial paints and coatings business in 2024?

The Problem: A railway systems company was experiencing issues with a twenty-year-old motor. Their production line starts with a conveyor that transports a saw to cut rail. The motor frequently...

By MCE and Parker Pneumatics Teams

Industrial process control valves are available in uncountable combinations of materials, types, and configurations. An initial step of the selection procedure for a valve application should be...

Parker Hannifin’s new Phastkrimp 2 is a bench-mounted crimper that meets the standards you expect with Parker Parkrimp. With a cycle time of 7 seconds, Phastkrimp 2 is the fastest Parkrimp machine...

How Switching to MCE’s Vendor Managed Inventory (VMI) Program Reduced Inventory Management Time by 80%

Creating an efficient inventory management system requires advance planning, and the help of an experienced inventory management team can make all the difference.

Efficient supply chain management can increase your profit margins. Too often, however, companies find themselves stuck in a reactive loop—firefighting stockouts, juggling last-minute orders, and...

Want to reduce stockouts, overstocks and downtime while improving reliability, cash flow and operational efficiency? Consider one of the inventory management methods that MCE offers for maximum...

Oil and water don’t mix – don’t let pollution be the result. Turn oily condensate from your air compressor into steam for synthetic and petroleum base lubricants with ThermaPhase. It leaves zero...

Municipal water and wastewater treatment plants depend on electric motors to drive essential equipment like pumps, aerators, and other critical systems. These motors endure heavy workloads and harsh...

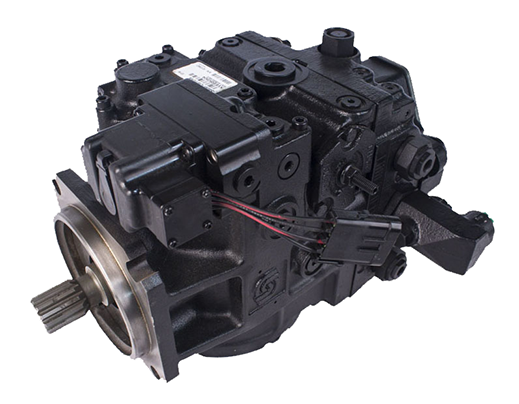

With 100+ Years of Experience We Get You Running and Keep You Running. Hydraulic Pump & Motor Repair

Looking for hydraulic repair or service to optimize your operations? We service, test, and sell hydraulic equipment to extend its life, salvage what we can from existing machines, and design new...

Maintaining pumps in water treatment plants is no small feat, especially when faced with corrosive environments, aging equipment, and strict compliance regulations. This is crucial for municipality...

Service and Repair Rotating Equipment

Proactive Maintenance Solutions for Glass Bottle Production Operations

Unplanned downtime costs industrial manufacturers $50 billion each year.

Look no further. Parker Series 2A Air Cylinders have undergone Parker’s rigorous inspection and performance tests—making them the perfect long-lasting choice for your operations. The 2A’s...

Hydraulic Accumulators are a staple in almost every industrial plant. Accumulators absorb shock and add volume to a hydraulic system at a fast rate. Maintaining the right pre-charge levels is...

Poor inventory management hurts more than purchase orders and balance sheets. The impacts of ineffective inventory control are far-reaching, touching every facet of manufacturing, from worker and...

Just as technology is making our cars and our homes “smarter”, it is also transforming traditional maintenance into becoming predictive instead of just preventative. This is allowing manufacturing...

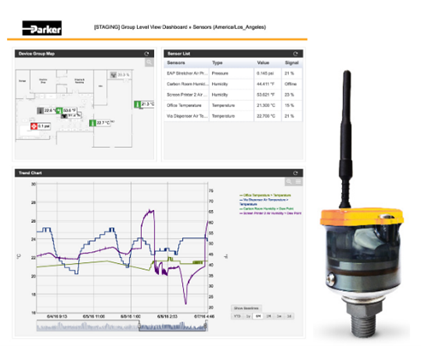

The greatest gift an operations engineer can have is the gift of time. When system conditions are deteriorating, time is the only thing that can keep a good day from becoming a very bad one. Parker’s...

In today's modern, fully automated manufacturing applications, assessing the potential risks to personnel is an essential part of overall system design. It’s vital to take appropriate measures to...

Denison Hydraulic Pumps Ensure Quick Repair Turnaround Time, Regardless of Complexity We are your Denison hydraulic pump and motor repair center. MCE company Nova Hydraulics’ experienced, trained...

The Challenge At 9 PM, an MCE steel customer ran out of spare pumps. Every minute spent waiting for a replacement was money down the drain. The customer, a bar mill creating square billets, called...

THE PROBLEM: A company’s machining center had a control system that was 20 years old. The controls and drives were no longer operational, but the machine’s mechanics were still able to operate within...

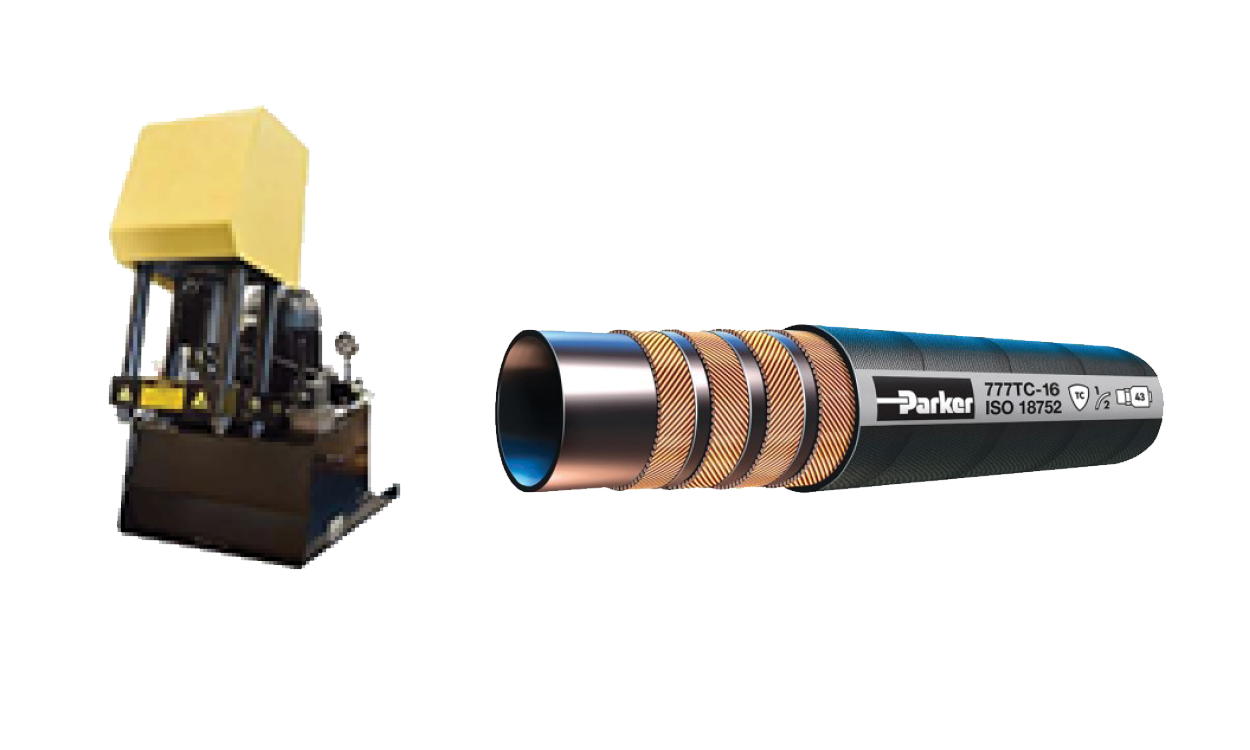

Hydraulic Hose Products With extensive local inventory and exceptional customer service by factory-trained personnel, we have a solution for you. Whether you work with industrial or mobile...

Compliance of EPA Clean Water Act CWA-404 Compressed air systems produce condensate that contains water, oil, and contaminants, posing environmental risks and potential EPA violations if not properly...

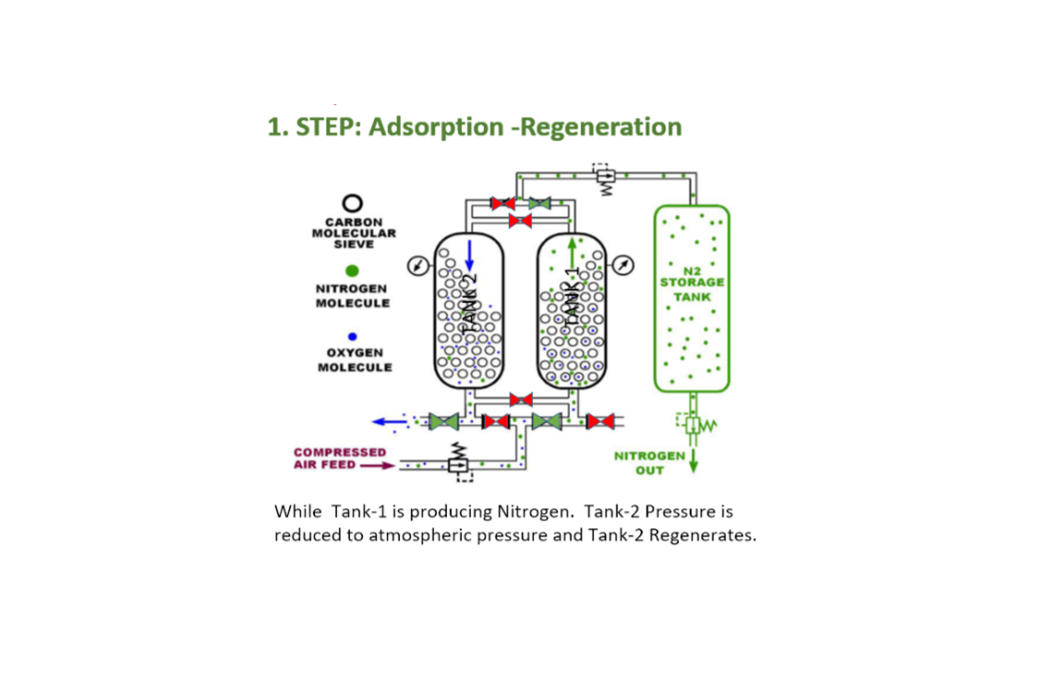

A customer needed help with a project requiring nitrogen generation, and Motion & Control Enterprises (MCE) stepped in and created a solution that resulted in cost savings, increased morale, and...

The Problem During a bi-annual planned outage, a Missouri customer consulted MCE company Lone Star Machine Works, for assistance with cylinder repairs. Six hydraulic cylinders needed to be fixed and...

To assist in compliance the recent OSHA Respirable Crystalline Silica (RCS) Standard, Parker’s Series 7084 Twinhammer™ Bonded Air/Water Jackhammer Hose is the first factory-assembled dual-hose system...

The Challenge: When our customer's main compressor unexpectedly failed, they faced a pressing need for a replacement before the year's end. They were also noticing moisture issues and having concerns...

Find your fit for Motion: A Guide to Pneumatic Solutions When motion is the challenge, MCE has the solution to move you. Motion solutions come in three major categories: hydraulic, electromechanical,...

THE PROBLEM: A Motion & Control Enterprises (MCE) customer was having an issue with plastic cap dumping machines used in an automated system. This customer was utilizing a ball screw...

The Problem: A small food packaging company near Pittsburgh encountered significant challenges with its compressor equipment. The company was dissatisfied with the service from a competitor who had...

THE PROBLEM Our customer needed to build a new machine for applying sealant and then feeding the lids into their end customer’s filling line. They needed a Canning Line Lid Seal Manufacturing System,...

When it comes to lubrication, adding grease guns is an obvious and affordable option to keep your operation running smoothly. But as you look to squeeze every ounce of efficiency out of your...

When it comes to choosing a rotary screw air compressor, you need to acknowledge the heat. Compressing air from 0 to 125 PSIG creates heat through the “heat of compression” process. The air needs to...

When motion is the challenge, MCE has the solution to move you. Motion solutions come in three major categories: hydraulic, electromechanical, and pneumatic. Learn the difference between the three to...

Electricity, water, and gas are all utilities that every plant requires to produce product and assure plant uptime. However, another utility is often overlooked and taken for granted, but is...

Condition monitoring like never before: Continuous. Non-interuptive. Safe. Parker’s SensoNODE™ Sensors and SCOUT™ Cloud Software provides continuous remote monitoring of asset performance that:...

Looking for instrumentation? You’ve come to the right place. MCE carries Parker instrumentation for nearly every industry. And as a premier Parker partner, we can get you the most competitive rates...

You May Qualify for a Significant Energy Rebate Up to $10K Think of air audits as just another cost to the business? Wrong! The department of Energy states that a facility that has never had a...

The state funded project required nitrogen for mold creation and Motion & Control Enterprises (MCE) generated the nitrogen solution that helped create an entirely new market for coal. Download this...

Vendor Managed Inventory (VMI) Services Customer Success: Save Time & Space with an Organized, Centralized Stocking Location A manufacturer and service provider of energy control and optimization...

There’s a simple answer to why industries of all types should be using oil free air compressors: No oil is introduced into the air or manufactured product! While this simple answer is the endgame for...

How Switching to MCE’s Vendor Managed Inventory (VMI) Program Reduced Inventory Management Time by 80% The Problem A customer who manufactures equipment for bridge inspections is in a very remote...

A customer found themselves frustrated with the high cost of bulk nitrogen and the associated fees of their nitrogen contract. The company called on Diversified Air Systems (DAS), a Motion & Control...

Just as technology has made our cars and homes smarter, technology is transforming industry as well. No matter what realm you work in, technological advances are making it easier for the machines we...

The company is a manufacturer ofsheeter machines, which cut paper or other materials atspecified lengths and widths. The Problem: A long-time user of Unitronics HMI/PLC products and customer of MCE...

Inline Spring Loaded Valve 1) Installation and Mounting Inline, spring loaded check valves can be used in horizontal or vertical applications with proper spring selection. This is most evident in...

The Problem A customer was meeting with Diversified Air Systems, an MCE company, for a routine visit to gather preventative maintenance information for an agreement. During the visit, the team...

Pressure spikes, flow surges, or temperature changes can render the electronics and components of your heavy equipment useless. Even regular maintenance cannot always prevent damage and costly...

Your current brand of diaphragm pump is functional, but is it simple, smart, sustainable, and easy to maintain? Our pumps go beyond expectations. Section 1: Energy Efficiency and Cost Savings By...

By MCE and Parker Hannifin Teams Source: https://blog.parker.com/site/usa/pneumatics-home/smart-pneumatics-role-in-automation-cobots-safety-and-system-efficiency For today’s industrial pneumatic...

Selecting the appropriate hydraulic hose for an application is not always easy. The aspects that define the suitability of a hose include, among others, media compatibility, working pressure,...

As important as electricity, water and gas are to any facility, most manufacturers also rely on a fourth utility. It comes in the form of a reliable supply of compressed air. Effective pneumatic...

By MCE and Parker Hannifin Pneumatics Teams Consider these questions: Do you have pneumatic applications in your facility that need to be energy isolated to keep your employees safe? Do you require...

To keep production processes lean and stocks low, the automotive supplier, NIDEC GPM Group, relies on the autonomous mobile robots from Mobile Industrial Robots. NICEC GPM is a customer of Industrial...

Like bi-annual dentist visits or your yearly physical, shutting down your plant for a health check is critical to the health, wellbeing, and longevity of your operation. And these outages are...

Industrial Internet of Things (IIoT), often considered the innovation for the future, is a term that gets used broadly to describe the connectivity of industrial application with modern technology,...

The Problem A customer faced these significant issues with his current compressor vendor.: The compressors were on the third floor of a historic landmark building, adjacent to the boiler room,...

The Rise of Artificial Intelligence Machine Learning in Manufacturing on the Factory Floor… By Ashley Ziatopolsky, from the AME 2024 Program In the world of manufacturing, a new application and...

Maintaining clean fluids and air is crucial in various industrial applications to ensure operational efficiency and equipment longevity. MCE offers a comprehensive range of filtration products to...

For a successful pneumatic system, choosing the right cylinder for your unique industry is essential. Responsible for converting compressed air into mechanical energy, pneumatic cylinders contribute...

By MCE company, Industrial Control MiR 250 Robot and Cart A fleet of seven autonomous mobile robots (AMRs) from Mobile Industrial Robots (MiR) works around the clock to optimize the transportation of...

The Problem The co-owners of a pizza company were in the early stages, focused onpizza crust production for distribution. The company used the air for the automation line from dough to cut moving...

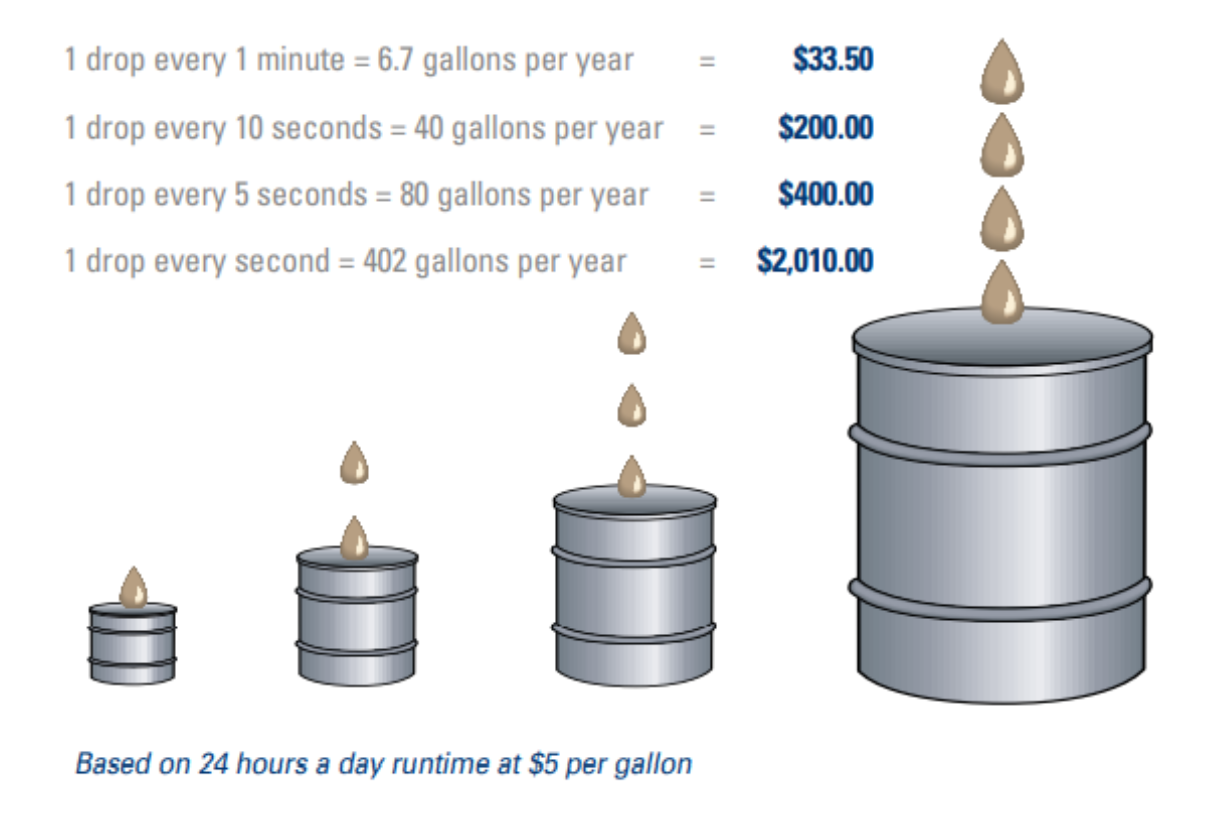

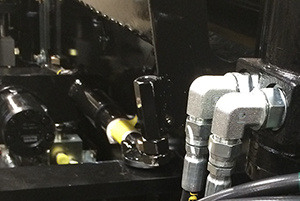

Hydraulic connection leakage can create hidden costs such as: Energy loss Safety hazards Environmental responsibilities Maintenance costs Lost sales Warranty To minimize hydraulic leakage and its...

The perfect introduction to Parker’s CLOUD-based monitoring solution. The SCOUT™ Cloud and SensoNODE™ Gold Starter Kit This easy to use Starter Kit allows you to test the benefits of using the SCOUT...

In the hustle and bustle of adopting and adapting to more digitized, profitable, efficient, exciting—and sometimes overwhelming—industry technology, upgrading your plant safety procedures may not...

Myth and misapplication are abundant when it comes to hydraulic fitting leaks. To keep yourself and your staff safe, here’s what not to do when you find a hydraulic fitting leak and why.

The MiR robot’s high payload capabilities, ease-of-use, and cleanroom compliance smooths the production flow for surgical instrument manufacturer Argon Medical Devices. The robot allows skilled...

How often do we say to ourselves, “if only I would have known sooner!” With industrial machinery, being able to know earlier if something is starting to fail can be the key to correcting a developing...

Nitrogen is the second-most widely used gas in industry. Tasteless, odorless, inert, and non-combustible, nitrogen is an important element used for a variety of different industrial purposes. But...

It's your first day on the job in a new [to you] industry and you are faced with a large amount of information. Everyone is using terminology that you’ve never heard before and you are hit with a...

For decades, affordable motion control solutions using hydraulics have been a staple in factory automation. Rugged and relatively low cost to deploy, the advantages of hydraulic solutions couldn’t be...

Hydraulic, pneumatic or lubrication systems should be efficient and leak free. Sometimes, they are not, because of improper tube line routing—the result of either lack of knowledge, or corners cut on...

Have you ever monitored equipment and scheduled a routine shutdown, only for a machine to break down out of nowhere? This shutdown skyrockets downtime and results in lost productivity, time, and...

How does crimper functionality differ among manufacturers? The result for all crimpers is virtually the same, but the crimping methods differ among manufacturers. One-way crimpers differ is whether...

The Problem A company was experiencing inefficiencies due to its aging dryer and compressors. During a routine service, a Diversified Air Systems, an MCE company, technician identified the problems...

When motion is the challenge, MCE has the solution to move you. Motion solutions come in three major categories, hydraulic, electromechanical, and pneumatic. Learn the difference between the three to...

By Parker Hannifin and MCE’s Fluid Power Teams Transair Pressurized System Outlet Hot tapping, or pressure tapping, is the process of adding a new connection to a piping system while under pressure....

FLEXIBILITY OF MOBILE ROBOTS SUPPORTS LEAN MANUFACTURING INITIATIVES AND CONTINUOUS OPTIMIZATIONS OF INTERNAL LOGISTICS AT HONEYWELL Three mobile robots from Mobile Industrial Robots (MiR) are...

There are no results for the filtering combination that you have selected.

Please try a different combination or broader filter options. To reset filters, uncheck all boxes and empty the search field.