Resources

Evidence of our expertise and how WE SOLVE PROBLEMS for our customers

Solutions

Industries

In industrial facilities, when motors don’t start, stop, or run correctly, production feels it.

ParkerStore™ is your go-to destination for hose, fitting, instrumentation, hydraulic, pneumatic, and filtration products and services. Our mission at MCE is simple: to help you improve productivity...

In industries where purity, product integrity, and regulatory compliance are non-negotiable, sanitary instrumentation plays a critical role. Among these instruments, sanitary gauges are essential...

When temperatures drop, pipes freeze, processes stall, and products spoil unless you have the right heat tracing system in place. Electric heat tracing is a critical safeguard for maintaining...

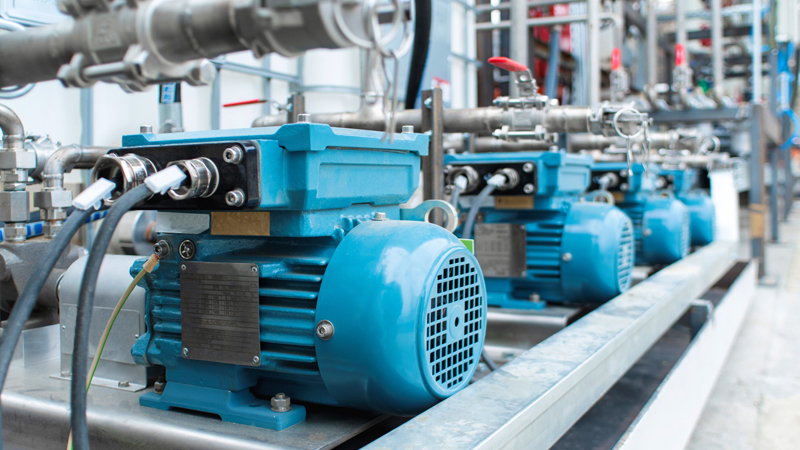

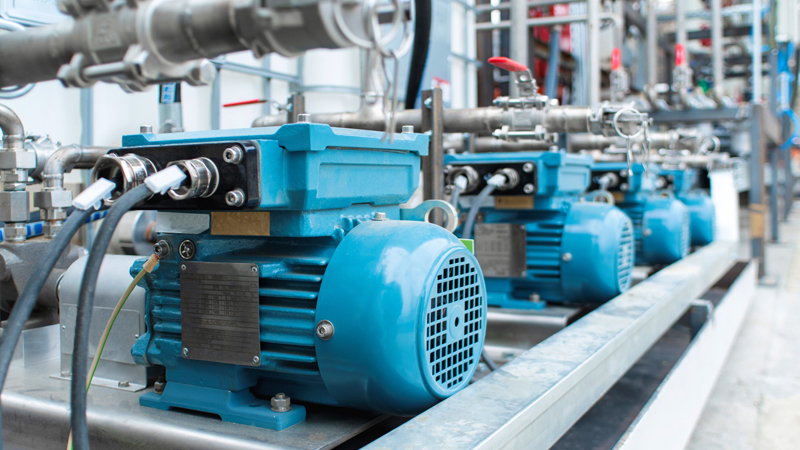

In water, wastewater, and industrial facilities, pumps are the heart of the operation. But like any piece of equipment, they don’t last forever. Knowing when to repair versus replace can save you...

As your operations grow more complex and regulatory expectations rise, you need instrumentation solutions from a partner you can rely on.

In a chocolate-making facility, uninterrupted flow is everything. A single blockage can halt production and trigger hours of cleanup.

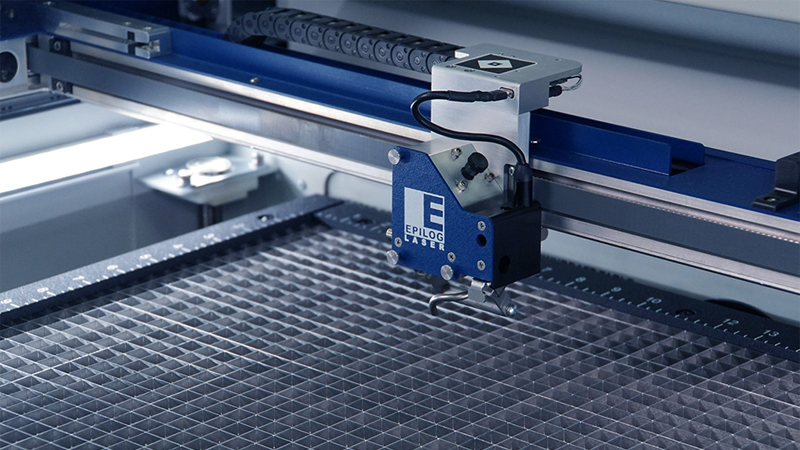

Automation from Start to Finish for Your Industrial Application with MCE Solutions.

Vertical farming is gaining traction as a reliable solution to address land scarcity and climate uncertainty. Controlled environment agriculture enables the growth of fresh produce near urban...

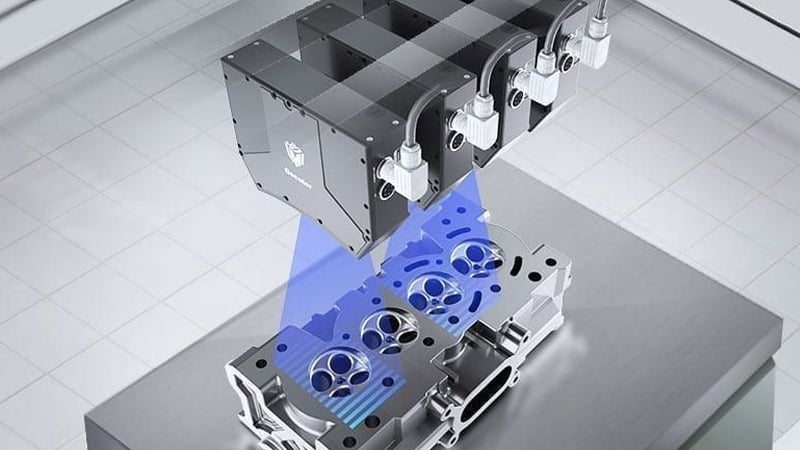

From defect detection to robotic guidance—MCE makes it work together. With deep expertise in vision and automation, we design 2D and 3D inspection systems that deliver clarity, reduce errors, and...

Pneumatic conveyers and engineered pump systems play vital roles in ensuring efficient and sanitary material handling and wastewater processes in food and beverage production.

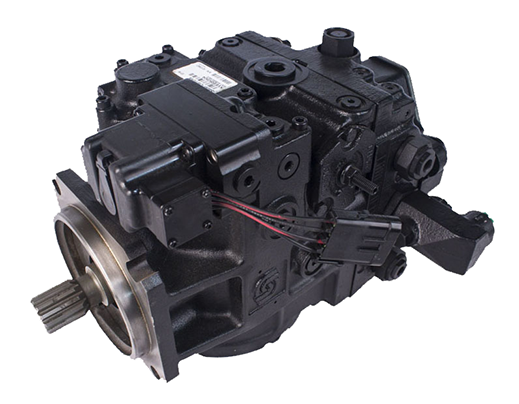

Fast Fix or Smart Swap—MCE Guides Your Choices for Critical Hydraulic Equipment

Avoid Downtime with MCE’s In-House Calibration Services. MCE Flow Control Solutions provide the capabilities to serve a wide range of applications within almost any industry.

Don’t let mining operations come to a halt due to equipment failure.

MCE: Your Compliance Partner for Component Traceability.

MCE: Creating a Partnership Built on Responsiveness and Results

Industrial and municipal operations face a complex reality: rising equipment costs, OEM delays, and technician shortages. With tight budgets and pressure to maintain uptime, teams are turning to...

Finding experienced instrumentation control (EIC) engineers can be challenging for industrial and municipal process plants. Here are some of the top reasons it's difficult: Aging workforce Niche...

Reduce noise, boost safety, and extend production equipment life with MCE.

Industrial plants lose millions every year due to equipment failures caused by inconsistent lubrication. MCE’s automated lubrication systems eliminate guesswork, delivering precise lubrication...

Pressed for additional warehouse space? Stop thinking about square footage—and start imagining cubic footage.

Downtime and operational inefficiencies in highly regulated industries translate to substantial financial losses and regulatory risks. What can you do to address these challenges?

Imagine discovering that invisible contaminants in your compressed air are compromising the quality and safety of your food production. Don’t let hidden risks turn into costly recalls—learn how to...

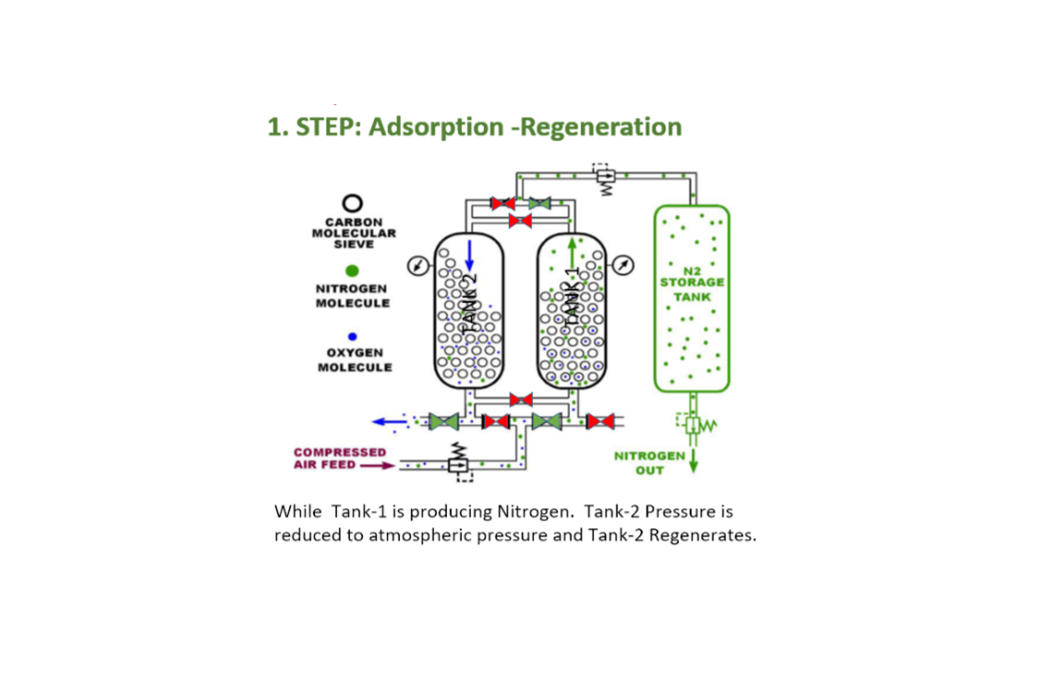

Every drop of your craft deserves perfection—so why risk oxidation, supply delays, and wasted nitrogen? Take control of your brewery or winery’s future with onsite nitrogen generation—where cost...

Are you paying more than you should for nitrogen in your food packaging operations? You’re not alone—a significant portion of the market relies on bulk liquid nitrogen, but that convenience comes at...

Downtime in the food and beverage (F&B) industry isn't just an inconvenience—it's a direct hit to profitability.

How Switching to MCE’s Vendor Managed Inventory (VMI) Program Reduced Inventory Management Time by 80%

Creating an efficient inventory management system requires advance planning, and the help of an experienced inventory management team can make all the difference.

Efficient supply chain management can increase your profit margins. Too often, however, companies find themselves stuck in a reactive loop—firefighting stockouts, juggling last-minute orders, and...

Want to reduce stockouts, overstocks and downtime while improving reliability, cash flow and operational efficiency? Consider one of the inventory management methods that MCE offers for maximum...

Oil and water don’t mix – don’t let pollution be the result. Turn oily condensate from your air compressor into steam for synthetic and petroleum base lubricants with ThermaPhase. It leaves zero...

With 100+ Years of Experience We Get You Running and Keep You Running. Hydraulic Pump & Motor Repair

Looking for hydraulic repair or service to optimize your operations? We service, test, and sell hydraulic equipment to extend its life, salvage what we can from existing machines, and design new...

Service and Repair Rotating Equipment

Proactive Maintenance Solutions for Glass Bottle Production Operations

Unplanned downtime costs industrial manufacturers $50 billion each year.

Poor inventory management hurts more than purchase orders and balance sheets. The impacts of ineffective inventory control are far-reaching, touching every facet of manufacturing, from worker and...

The Challenge At 9 PM, an MCE steel customer ran out of spare pumps. Every minute spent waiting for a replacement was money down the drain. The customer, a bar mill creating square billets, called...

The Challenge: When our customer's main compressor unexpectedly failed, they faced a pressing need for a replacement before the year's end. They were also noticing moisture issues and having concerns...

The Problem: A small food packaging company near Pittsburgh encountered significant challenges with its compressor equipment. The company was dissatisfied with the service from a competitor who had...

THE PROBLEM Our customer needed to build a new machine for applying sealant and then feeding the lids into their end customer’s filling line. They needed a Canning Line Lid Seal Manufacturing System,...

When it comes to choosing a rotary screw air compressor, you need to acknowledge the heat. Compressing air from 0 to 125 PSIG creates heat through the “heat of compression” process. The air needs to...

When motion is the challenge, MCE has the solution to move you. Motion solutions come in three major categories: hydraulic, electromechanical, and pneumatic. Learn the difference between the three to...

Electricity, water, and gas are all utilities that every plant requires to produce product and assure plant uptime. However, another utility is often overlooked and taken for granted, but is...

Looking for instrumentation? You’ve come to the right place. MCE carries Parker instrumentation for nearly every industry. And as a premier Parker partner, we can get you the most competitive rates...

You May Qualify for a Significant Energy Rebate Up to $10K Think of air audits as just another cost to the business? Wrong! The department of Energy states that a facility that has never had a...

The state funded project required nitrogen for mold creation and Motion & Control Enterprises (MCE) generated the nitrogen solution that helped create an entirely new market for coal. Download this...

Vendor Managed Inventory (VMI) Services Customer Success: Save Time & Space with an Organized, Centralized Stocking Location A manufacturer and service provider of energy control and optimization...

There’s a simple answer to why industries of all types should be using oil free air compressors: No oil is introduced into the air or manufactured product! While this simple answer is the endgame for...

How Switching to MCE’s Vendor Managed Inventory (VMI) Program Reduced Inventory Management Time by 80% The Problem A customer who manufactures equipment for bridge inspections is in a very remote...

A customer found themselves frustrated with the high cost of bulk nitrogen and the associated fees of their nitrogen contract. The company called on Diversified Air Systems (DAS), a Motion & Control...

THE PROBLEM: A chemical plant was installing a water runoff drainage system in their parking lot and needed an end-of-line solution to shut off the flow of water, enabling measurement and adherence...

The Problem A customer of Swanson Flo, an MCE company, was using a manual regulator to control the air flow into a peristaltic pump. However, the manual regulator was not providing the levels of...

The Problem A customer was meeting with Diversified Air Systems, an MCE company, for a routine visit to gather preventative maintenance information for an agreement. During the visit, the team...

As important as electricity, water and gas are to any facility, most manufacturers also rely on a fourth utility. It comes in the form of a reliable supply of compressed air. Effective pneumatic...

By MCE and Parker Hannifin Pneumatics Teams Consider these questions: Do you have pneumatic applications in your facility that need to be energy isolated to keep your employees safe? Do you require...

The Challenge: Facing steam leakage issues, a customer sought help from Justin Timmerman, an Outside Sales Representative, and the Swanson Flo team. Upon investigation, Justin discovered that the...

The Problem A customer faced these significant issues with his current compressor vendor.: The compressors were on the third floor of a historic landmark building, adjacent to the boiler room,...

Maintaining clean fluids and air is crucial in various industrial applications to ensure operational efficiency and equipment longevity. MCE offers a comprehensive range of filtration products to...

The Problem The co-owners of a pizza company were in the early stages, focused onpizza crust production for distribution. The company used the air for the automation line from dough to cut moving...

Nitrogen is the second-most widely used gas in industry. Tasteless, odorless, inert, and non-combustible, nitrogen is an important element used for a variety of different industrial purposes. But...

The Problem A company was experiencing inefficiencies due to its aging dryer and compressors. During a routine service, a Diversified Air Systems, an MCE company, technician identified the problems...

By Parker Hannifin and MCE’s Fluid Power Teams Transair Pressurized System Outlet Hot tapping, or pressure tapping, is the process of adding a new connection to a piping system while under pressure....

Using a steam system requires not only ensuring steam is working properly but also managing the bi-productof that steam creation, steam condensate. If not safely removed, steam condensate can cause...

There are no results for the filtering combination that you have selected.

Please try a different combination or broader filter options. To reset filters, uncheck all boxes and empty the search field.