Are you paying more than you should for nitrogen in your food packaging operations? You’re not alone—a significant portion of the market relies on bulk liquid nitrogen, but that convenience comes at a cost.

While having nitrogen delivered to your facility may seem like an economical business practice, you’re often paying for more than nitrogen alone. Delivery fees, rental charges, and even evaporation losses can add up quickly.

Switching providers isn’t always simple either. Many suppliers lock businesses into long-term, auto-renewing contracts requiring up to 12 months' notice for cancellation. Miss that window, and you could be stuck for years.

So how can you escape these costly contracts and unpredictable expenses? By generating nitrogen in-house.

With in-house nitrogen generation, you control purchasing and can cut gas costs by 50%–90%. Though useful in various industries—metals, chemicals, pharmaceuticals—food and beverage operations see some of the greatest advantages.

Understanding Nitrogen Gas Use in Food Packaging and Production

Nitrogen gas (N2) makes up about 78% of the atmosphere. It’s available in liquid or gas form, delivered or generated onsite.

Nitrogen plays a major role in your food packaging and production operations.

Food-grade nitrogen displaces oxygen in packaging, extending shelf life and reducing spoilage. Bacteria thrive on oxygen, so its removal helps prevent growth. But that’s not the only benefit.

Nitrogen enhances food safety and quality. Here's how different foods benefit from nitrogen during packaging:

- Preserving freshness: Prevents spoilage due to oxidation.

- Protecting delicate foods: Provides cushioning in packaging for items like berries or leafy greens.

- Maintaining appearance: Helps fruit and vegetables retain color by limiting oxygen exposure.

- Snack food packaging: Keeps snacks like chips and pretzels crispy and intact.

- Fresh meat packaging: Inhibits bacterial growth to extend shelf life.

- Coffee packaging: Preserves aroma and flavor by reducing oxygen exposure.

- Bagged salads and greens: Maintains crispness and freshness of leafy vegetables.

- Bottling: Displaces oxygen to extend beverage shelf life.

Nitrogen is also used during food production:

- Sparging: Removes oxygen and volatile substances in liquids (e.g., wine).

- Fluffing: Alters texture and density in fats and mayonnaise.

- Nitrogen injection: Adds micro-bubbles in creams and desserts.

- Nitrogenating: Adds texture and foam in brewing.

Why Nitrogen Generation Makes Sense for Food Production and Packaging

Generators allow businesses to produce nitrogen on demand—cheaper and more reliable than bulk delivery. Systems vary by purity, flow rate, and pressure needs.

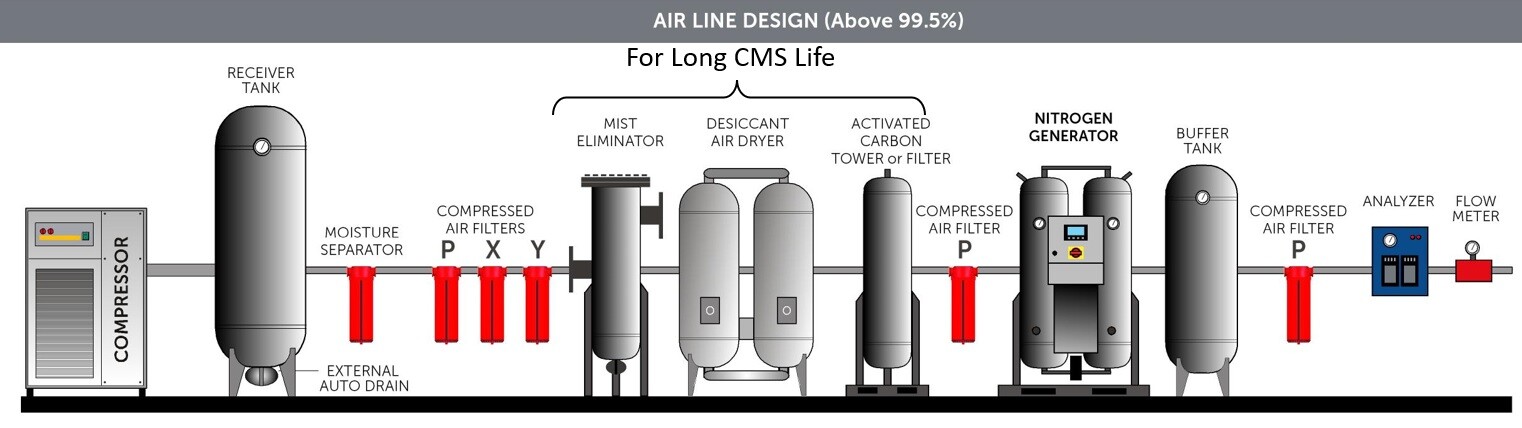

Typical system components include a compressor, filters, CMS columns, a receiver tank, and a pressure outlet.

Considerations include desired purity (99.5–99.9%), flow rates, and inlet/outlet pressures. Maintenance is minimal—routine filter changes and compressor servicing.

Industries benefiting from nitrogen generation include:

- Snack and ready-to-eat foods

- Coffee packaging

- Meat and poultry processors

- Wine production

- Breweries and micro-breweries

Key Benefits of Nitrogen Generators for Food Packaging and Production

Onsite nitrogen offers a clean, inert atmosphere that helps extend shelf life and reduce spoilage, oxidation, and contamination. Benefits include:

- Longer shelf life

- Less oxidation

- Reduced bacterial growth

- Preserved color, taste, and texture

- Lower product waste and recall risks

- Lower operational costs

- Reduced environmental impact

- Consistent gas purity

- Safer workplace (reduced combustion risks)

- Improved food safety

Concerned about cost? A nitrogen generator can pay for itself in just 12–18 months.

Compared to bulk delivery, onsite generation is more affordable and scalable. Avoid price hikes and long-term contracts while reducing environmental risk.

Bulk suppliers charge for the gas, rental, delivery, surcharges, and admin fees. Prices rise with fuel costs and long-term contracts often include annual rate hikes.

Liquid nitrogen loses up to 15% to boil-off. Contracts lock businesses into 3–10 years with potential 15% yearly increases.

Switching to onsite generation eliminates those costs. Average price drops to $0.07–$0.12 per 100 cubic feet depending on energy and purity.

Hidden costs of traditional nitrogen: (Rates may vary)

Hidden costs of traditional nitrogen: (Rates may vary)

- Tank rental: Up to $2,000/month

- Delivery fees: $25–$75/month

- Environmental surcharges: $35/month

- Boil-off: Up to 15%

- Annual price increases: ~15%

- Contract terms: 3–10 years

- Administrative fees: Added costs for invoicing

In-house generation can be 50%–90% cheaper.

- $0.08–$0.12 per 100 cubic feet

- No tank rentals or delivery charges

- No long-term contracts

- ROI in 6–24 months

- Low maintenance and operating costs

It’s also better for the environment. Cut costs and CO2 emissions by switching to in-house nitrogen. Let Diversified Air design a system tailored to your operation.

Why Choose MCE for Nitrogen Generation

You promise high standards—quality, efficiency, safety. We help you deliver on that promise.

Partner with MCE and get expert guidance in choosing a nitrogen solution tailored to your needs. We offer more than equipment—we’re with you through install, service, and support.

What we offer:

- System Audits: Onsite evaluations to identify system inefficiencies.

- Turnkey Solutions: Fully integrated installations to minimize downtime.

- Preventive Maintenance: Scheduled service to maintain nitrogen purity and uptime.

- Custom Design: Systems tailored to high-volume or niche packaging needs.

- Inventory & Services: Access to a broad range of plant parts and services—pumps, motors, valves, and more.

Gain control, lower costs, and improve efficiency with nitrogen generation. Let MCE help make it happen.