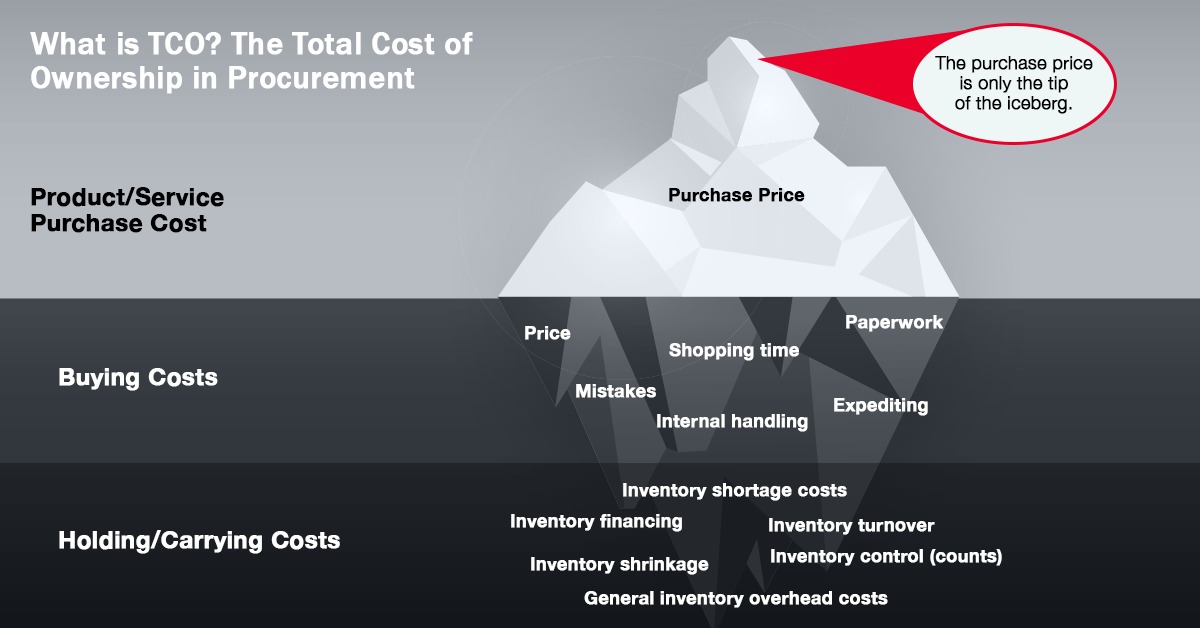

Unexpected costs are common, and inventory management is no exception. Getting control of your bottom line lies in understanding and paying attention to often overlooked expenses.

Just like concert tickets or takeout orders, where fees and charges quickly double the initial price, the hidden costs of inventory can add up over time. These costs aren’t always obvious, but if overlooked, they can eat into your margins and impact profitability.

With inventory management, the extra costs can be harder to suss out because they’re spread over time. Not only is the purchase price of your inventory important, but there are also substantial costs associated with owning and managing that inventory that add up to the total cost of inventory. And if you’re not conscious and careful about them, they can reduce your profitability.

Understanding the Total Cost of Ownership (TCO) is key to managing these expenses. Let’s explore the major elements of TCO and how to keep them in check.

What is the total cost of ownership in procurement (TCO)?

And what costs are included? The costs of procuring inventory fall into two separate buckets:

Buying costs – include everything from the time spent locating merchandise, or shopping and negotiating prices, to paperwork, shipping and receiving, and handling errors and returns.

Holding and carrying costs – include everything inventory-related, from the warehouse space to financing, inventory control and shrinkage, and general overhead costs like taxes and insurance.

These costs are reflected in the Total Cost of Ownership: what it costs you to own and manage your stock once it’s in your possession.

TCO can be broken down further into three components:

- Direct Costs: These include the costs associated with acquiring, handling, and storing your inventory.

- Indirect Costs: These include the costs of labor, equipment, and technology — not just hiring and acquiring, but the ongoing expenses of maintenance and staying up to date.

- Hidden Costs: These include everything from loss of items due to damage or theft, as well as stock that becomes obsolete.

Shining a Light on the True Costs of Ownership in Procurement

With that in mind, here’s a breakdown of the most important elements you need to assess in order to understand your true TCO.

1. Carrying Costs. The more stock on your own premises, the more capital is tied up in inventory, which limits your financial maneuverability. This can also lead to substantial inventory financing costs, including loan maintenance fees and interest.

But that’s just the beginning — because the larger your inventory, the higher the associated storage costs. That includes the cost of buying or leasing warehouse space and everything associated with it, from climate control and security systems to equipment like forklifts, pallets, and bins.

A strong distributor relationship can really help lower your carrying costs because the distributor is holding the inventory until you need it. A strong industry-focused supplier has access to a large number of inventory items, which will allow you to be confident in knowing they’ll have the required parts when needed.

This is especially true if the distributor offers Proactive Inventory Stocking Agreements, such as MCE makes available through their VMI program that positions dedicated inventory in an MCE warehouse.

2. Order and Setup Costs. Keeping your inventory leaner and placing more frequent orders on a Just-In-Time basis is one way to reduce inventory storage costs. But if you’re not careful, the volume of orders and frequent restocking can be cumbersome.

The answer here lies in automation. MCE uses inventory management technology like Clear Spider to streamline and simplify ordering processes — in some cases reducing an eight-step process down to as few as three. MCE's tech-enabled approach also reduces manual errors, which helps avoid indirect costs linked to order inaccuracies.

>> How MCE helped one customer reduce inventory management time by 80%

3. Excessive Inventory Locations and Suppliers. Inefficient inventory operations can have significant costs, especially when inventory is spread out and managed through multiple suppliers.

MCE recommended consolidation. By leveraging its extensive catalog of parts, MCE helped a client reduce their number of suppliers from nearly 100 to just three, streamlining the ordering process and reorganizing their warehouse layout.

These improvements led to significant cost savings, including reduced logistical expenses, better inventory tracking, and lower supplier management fees.

>> How MCE helped car wash equipment manufacturer reduce logistical expenses

4. Stockout Costs. Although maintaining large amounts of stock can balloon your inventory costs, when you don’t have enough stock to meet demand, there’s an impact on customer satisfaction and potential lost sales.

The key is partnering with a supplier like MCE who can meet your needs timely while relieving you of the burden of carrying safety stock. MCE’s VMI program helps maintain optimal inventory levels across your facility.

>> How MCE's VMI program increased efficiency and reduced stockouts at aerospace manufacturer

5. Obsolescence and Shrinkage. Holding excess inventory increases the risk of stock becoming unsellable. It also requires more oversight to prevent theft, damage, or clerical errors — increasing personnel costs.

6. Opportunity Costs. Overstocking limits capital for other business investments, reducing agility and response time to market shifts.

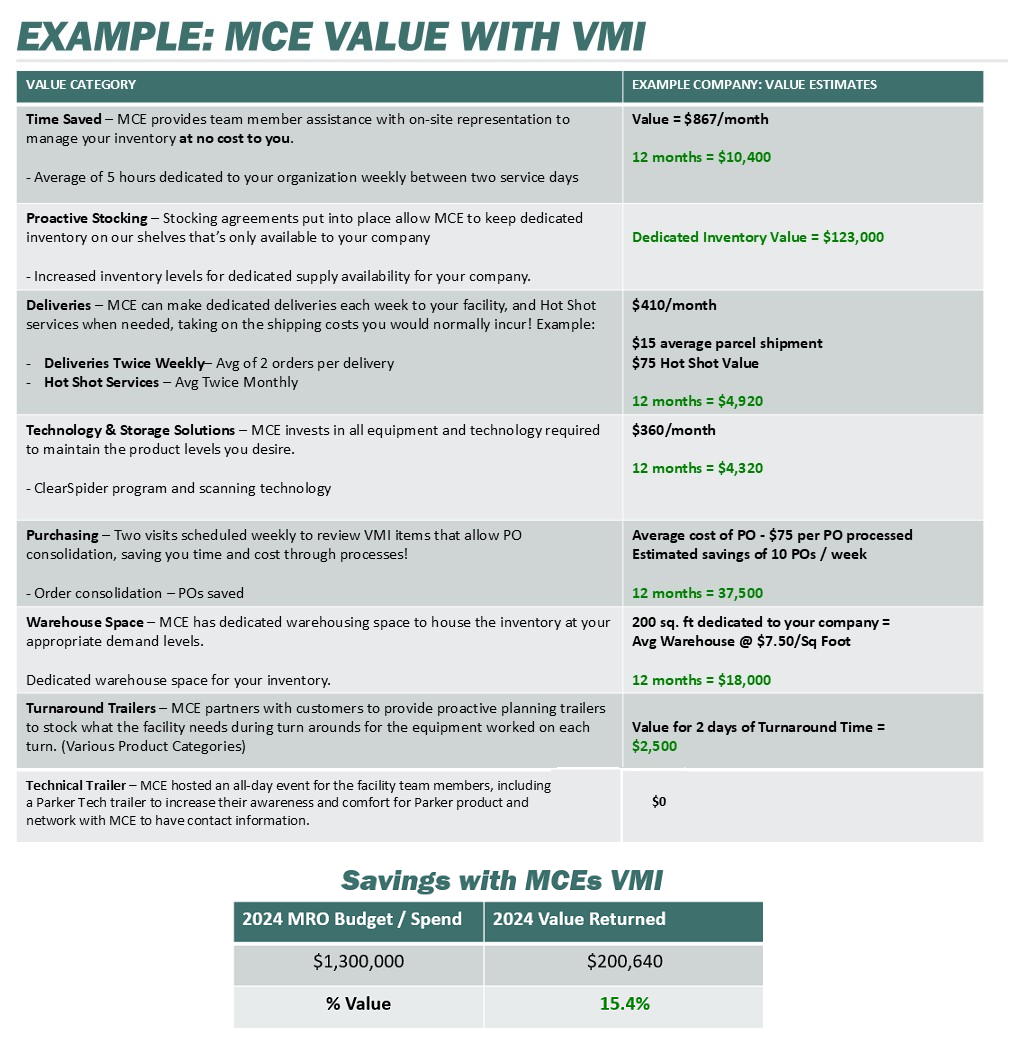

Total Value of MCE Inventory Management: Tracking Your Spend with MCE Scorecard

MCE tracks the value delivered to customers with an annual scorecard, aiming for a value return range of 8–12%.

For example, one customer with $1.3M in MRO inventory spend in 2024 saw a 15.4% return through services like:

- Onsite inventory tracking by an MCE rep

- Proactive stocking of critical parts

- Dedicated deliveries and Hot Shot services

- Inventory tracking app to optimize levels

- Purchase order consolidation

- Freeing up warehouse space via MCE storage

- Access to Turnaround trailers during plant maintenance

It's not just a scorecard — it's a way for customers to identify and capture additional value from MCE solutions.

How MCE Can Help You Rein in Your TCO

MCE’s digital tracking and barcoding improve inventory accuracy and reduce hidden costs. Their flexible solutions — VMI for larger clients, CMI for smaller ones — ensure customers only pay for the service level they need.

By customizing stocking agreements based on usage and lead time, MCE prevents overstocking and reduces emergency order costs.

Interested in learning more about how MCE can help you control your inventory costs? Contact us for a free assessment and find the right solution to manage inventory effectively while increasing your margins.