Florida’s rapid population growth is putting enormous pressure on its aging municipal infrastructure, especially lift stations and pump systems. Pump systems designed for a few hundred homes now routinely serve twice the load.

The result is more clogs, more overflows, and more emergency callouts that drain budgets and frustrate maintenance crews.

What worked for 200 homes a decade ago may now be dangerously undersized for double the demand.

Use our free capacity checklist to evaluate your lift stations.

Growth Is Outpacing Municipal Wastewater Infrastructure

Florida’s geography means almost everything must be pumped. In a city like Jacksonville, where flat topography is the norm, thousands of pumps keep wastewater flowing. By comparison, a hillier city like Columbia, S.C., may operate only a couple dozen stations.

As suburbs sprawl and mixed-use developments multiply, older stations are pushed far beyond their design limits. New construction loads increase daily flow, and some municipalities haven’t upgraded decades-old legacy pump systems to match current population density.

These stresses are exactly what MCE's experts see every day in the field. Rapid growth and aging equipment collide to create chronic ragging, rising maintenance costs, and major problems for the public.

Warning Signs of Wastewater Pump Failure

Lift station pumps are powerful systems that move sewage or wastewater from a lower elevation to a higher one when gravity flow isn’t possible.

Whether in Central, Southwest, or North Florida, municipalities experience the same indicators of an undersized or overworked lift station.

Common red flags include:

- Frequent pump clogs and ragging, especially in stations with older impeller designs

- Rising electrical consumption or maintenance hours tied to inefficient runtimes

- Overflow alarms and environmental fines that expose system vulnerabilities

- Pumps running nearly 24/7, rather than cycling normally

- Foul odors or even sewage backups

These issues rarely appear overnight; they build gradually and have worsened with population growth. High humidity and corrosion exacerbate these problems.

When does pump failure happen?

Lift station clogs tend to occur when most people are at home, especially during nights and weekends. This is also when maintenance crews are more limited and more expensive. It typically takes two technicians between four and six hours each to repair these pumps, putting strain on an already limited labor force and accelerating capital expenditures on assets.

But it doesn’t end there. Frequently clogged pumps overwork the pump system, burning out motors and components, overloading breakers, and increasing maintenance costs. Forget if you need to call out a vacuum truck; you’re looking at an easy $500 per visit.

The even bigger problem?

No matter how diligent these maintenance teams are, or how hard they work, the risk is always there for sewage and wastewater to back up into neighborhoods, schools, and businesses. These overflows not only put the public at risk, but they also trigger environmental and regulatory fines that can exceed $100,000.

Related: 5 Signs It’s Time to Replace (Not Repair) Your Pump

There’s a Better Pump Design. And Here’s the Proof

Many utility department heads have grown skeptical of “no clog” claims from different pump vendors over the years. So, it’s no wonder that trust is low (or nonexistent) until pump performance can be proven.

“Don’t tell me your pump works better. Show me.”

They are hesitant to believe a different pump can perform better in tough conditions. To justify the hoops they have to jump through to get new products on the approved vendor list, they need the pump to work. Flawlessly.

To them, the proof is in the performance.

That’s why when addressing these clogged pumps, our team of pump and power experts recommend ShinMaywa for clog-free operation. And they have the proof to back it up.

Want to try ShinMaywa pumps in your worst lift station? We offer worry-free demos.

Proof from Florida’s Toughest Lift Stations

Our team of pump and power experts understands the frustrations facing vital infrastructure leaders. You’re under extreme pressure to ensure proper water and wastewater flow throughout your community.

Obviously, a ragged-up pump can lead to decreased performance, increased operating costs, and equipment failure. But let’s not forget we’re talking about public sewage. If a pump cannot keep up with flow, that wastewater can back up and overflow into streets, yards, and local waterways.

Pump reliability matters.

Our sales team has documented several real-world cases where municipal customers struggled with chronic pump failures. After upgrading to ShinMaywa pumps through MCE, those systems saw major improvements in reliability. Below are a few of those examples:

JEA – Jacksonville Region: Non-Clog Performance Since 2016

Jacksonville Electric Authority (JEA) operates thousands of pumps, making it one of the largest wastewater utilities in the Southeast. In 2016, JEA tried ShinMaywa in a notoriously difficult ragging station after other competitor pumps (including top-tier brands) had failed.

Result: They worked with MCE to get a ShinMaywa pump, and clogs and callouts have been greatly reduced for the last nine years.

COVID-era cleaning wipes exacerbated clogging across JEA’s system. So, JEA started replacing any pump that clogged (even new ones) with ShinMaywa.

Our courtesy on-site pump testing ensures pumps are correctly sized.

City of Ocala: From Twice-Weekly Clog to Multi-Year Run Time

One station in Ocala was clogging twice a week, usually nights and weekends, creating staffing nightmares and overtime costs. In 2020, Ocala worked with MCE on a side-by-side trial: one new ShinMaywa pump next to an existing competitor’s pump.

Result: The competitor pump clogged within days; the ShinMaywa provided by MCE virtually eliminated clogging. Ocala ultimately rewrote its spec to include ShinMaywa and made a stocking order. The original demo pump is still running clog-free in 2025.

Palm Coast: Nightly Clogs to Virtually Eliminating Clogging

A rapidly growing neighborhood had converted a manhole in the middle of a roadway into a makeshift lift station. Nightly clogs from wipes and other debris caused high-amperage trips and shutdowns. Crews were spending their nights coning off the road, working in the dark, and often returning the next morning because of persisting problems.

Result: MCE recommended the ShinMaywa demo pump and after installation, the station went three months with virtually no clogs, a first for that site. The utility director immediately committed to future ShinMaywa purchases.

City of Ocoee: From Discontinued to Dialed In

Previously loyal to a competitor brand, the city needed a replacement for a discontinued pump with no available specs. Our team performed field testing, including a drawdown to determine performance, and selected the correct ShinMaywa model to meet those demands.

Result: The pump solved the issue, and Ocoee now requests ShinMaywa for all pumps under ~25 HP.

Toho Water Authority - Kissimmee: Chronic Callouts to Consistent Stability

Toho manages many lift stations, including their worst-performing station, which required vacuum truck callouts every other day.

Result: After installing a ShinMaywa demo pump, the station has gone nine months with no vacuum events. Toho is now evaluating wider adoption and standardization.

Haines City: Test Installs to 20 Stations... and Counting

After a chance cold-call meeting with the utility’s director, our expert introduced ShinMaywa pumps into a handful of problem stations. They solved chronic clogging, leading to rapid expansion.

Result: Pumps now operate in ~20 of the city’s stations, with movement toward full specification approval and inventory stocking.

Naples: Problem Station to Proof Point

What began with MCE calling to offer helpful suggestions turned into real traction when Naples staff asked to test a pump in a troublesome station.

Result: The ShinMaywa pump virtually eliminated clogging for two months, an unprecedented feat for that station, leading to fewer maintenance calls and reliable performance. Naples adopted ShinMaywa as an approved vendor, began purchasing multiple pumps, and now buys directly under a sole-source contract.

Why MCE Trusts ShinMaywa for Lift Station Pumps

ShinMaywa has over 65 years of wastewater experience and in manufacturing industry-leading submersible pumps, submersible mixers, bar screens, and blowers appropriate for both municipal and industrial use.

ShinMaywa makes a better pump for municipal wastewater lift stations because of its unique impeller design that offers superior clog resistance, allowing solids and high fibrous materials to pass through easily while remaining energy efficient.

Let’s talk about the design.

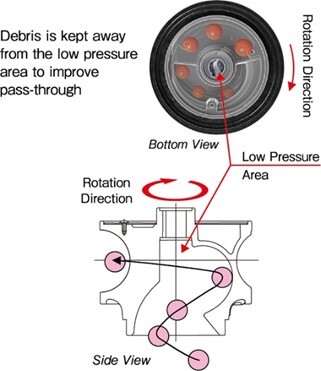

ShinMaywa CNWX Pumps feature a revolutionary single-vane non-clog impeller design. The SCROLL IMPELLER™ design incorporates a helix-formed passage at the inlet, which is smoothly connected to the single vane non-clog passage.

This scroll impeller design guides solid materials through the pump smoothly, while some models have a chopper mechanism that grinds stringy debris before it enters the impeller.

The CNWX series of non-clog scroll submersible pumps have high pass-through capability that can exceed that of current submersible pumps. This design virtually eliminates clogging, plugging, and entangling of fibrous materials resulting in reduced maintenance costs and electrical power consumption. Product details.

How Traditional Pumps Operate and Fail (vs. ShinMaywa’s Pump Solution)

Traditional, legacy pumps struggle in Florida lift stations due to severe clogging from modern non-biodegradable debris (cleaning wipes, rags, grease) and accelerated corrosion from Florida’s hot, humid environment.

Many pump stations are old, and their components are nearing the end of their operational lifespan. They were designed for lower flow rates and less demand than what we’re seeing today.

The result? More clogs.

Here’s how ShinMaywa is different from your existing pump:

Notice Clogs at the Center of the Impeller?

Traditional impellers create a low-pressure zone at their center (“the eye”). Debris like rags, toiletry items, or hair tends to accumulate in this low-pressure area and cause clogs.

ShinMaywa addressed this by switching to a scroll impeller, which changes the water’s path to a smoother quarter-turn flow. This design eliminates the low-pressure zone, preventing debris buildup in the impeller center.

Notice Clogs Between the Impeller and the Pump Casing (Volute)?

There is always a small gap between the spinning impeller and the casing. As components wear, this gap widens, making it easier for debris to get trapped. High discharge pressure can cause water to flow backward through the pump (“discharge recirculation”), carrying debris into that gap. Over time, debris accumulation can jam the impeller and stop the pump completely.

To combat this, ShinMaywa added a small O-ring between the impeller and the volute. When discharge recirculation occurs, pressure pushes the O-ring into place, sealing the gap and preventing reverse flow of water and debris. Combined with the scroll impeller, this eliminates both major clogging points.

Our customers have said: “Once you try ShinMaywa pumps, it’s hard to go back to another brand.”

Perpetually Clogged Pumps? Here’s What You Can Do

Municipalities can act before failures escalate into costly backups. Here are several proactive steps to identify and address undersized lift stations and ineffective pumps:

- Schedule an on-site lift station survey to evaluate equipment condition, pumps, and controls

- Recalculate the design load based on current housing density and flow projection

- Review pump runtime trends to detect increasing demand or inefficiencies

- Consider high-capacity, lower-maintenance pumps such as ShinMaywa models, which are reliably handling Florida’s newer wastewater challenges

- Upgrade control panels to improve monitoring and response during high-flow periods (typically nights and weekends)

How MCE Can Help Florida Municipal Customers

We are deeply involved in the consulting, design, sales, and service of lift station pumps throughout Florida and have been for decades. We get it. It’s not easy to switch brands you’ve been using for years or to get them on the approved brand list for your municipality. We make the process easy.

Our team provides:

- On-site flow and thread pressure testing to ensure pump sizing before installation

- Pumps and control panels engineered for Florida’s unique wastewater conditions

- Retrofits and rehabilitations that bring older stations up to modern standards

- Emergency service and long-term maintenance to keep stations operational

- Free demos or trial installations with delayed invoicing for procurement

- Fast availability from stocked regional warehouses.

You can’t stop growth, but you can get ahead of system failure. MCE Power and Pumps experts work with municipalities across Florida, and beyond, to engineer right-sized replacements, integrate smart controls, and prevent costly shutdowns.

Download Checklist: 4 Ways to See if Your Lift Station is Undersized

Ready to Try ShinMaywa Pumps in Your Worst Lift Station?

Your community deserves wastewater systems that keep up with demand. Ready to assess your system? MCE municipal specialists:

- Help diagnose chronic lift station problems

- Size and install a trial pump in the toughest locations

- Prove reliability before any commitment

Book a consult with our municipal pump experts today.